District of Kitimat Water Treatment Upgrades

2022-ongoing | Kitimat, BC

Direction from regulatory bodies to meet provincial water treatment objectives is motivating municipalities, particularly those who use surface water as a drinking water source, to upgrade their treatment processes.

Kitimat has long relied on chlorine-treated surface water from the Kitimat River to supply its community water system. While the water quality in the Kitimat River is generally good, high rainfall events have historically led to turbidity issues (clouding of water with particulate). These elevated turbidity levels can impact the effectiveness of chlorine to adequately disinfect the water and can increase the risk of pathogens. As a result, boil water notices are periodically issued to Kitimat community members.

In 2019, Kitimat began work to meet the new provincial guidelines. In 2022, McElhanney was engaged to design a new water treatment plant (WTP) for the District of Kitimat featuring an up-flow clarifier and filtration process for the surface water source. When complete, the WTP will serve a community of approximately 8,000 people and will have the capacity to meet the needs of the future community. The upgrades will improve disinfection and enhance the removal of turbidity, suspended solids, and colour from the water.

Creating a Water Treatment Plant with Progressive Design

To expediate the project in meeting provincial water quality objectives, McElhanney used a progressive design model that created project delivery efficiencies and helped avoid price escalations. Because equipment is sourced throughout the progressive design process, this approach supported the design of a compact building based on known equipment dimensions.

Water Treatment Plant Pilot Testing

McElhanney designed a pilot plant facility and supported Kitimat operations with the completion of pilot plant testing. The objective of the pilot study was to provide on-site operational experience for Kitimat staff and to collect data to support process equipment selection and chemical dosing system design. The information collected during the pilot plant study was used in the plant’s upgrade design.

Optimizing a Water Treatment Plant Within a Constrained Footprint

McElhanney’s in-house structural, process, electrical, and civil disciplines coordinated to design the plant for a constrained footprint. Multiple utilities, existing buildings, challenging topography, and property boundaries influenced the orientation and location of the plant. With the constraints of the small building footprint in mind, the size of the plant (and ultimately the capital spend) was optimized to balance expected population growth and water conservation measures. McElhanney performed an in-depth review that informed this optimization, and this review approach was featured in a 2024 BCWWA Annual Conference technical presentation.

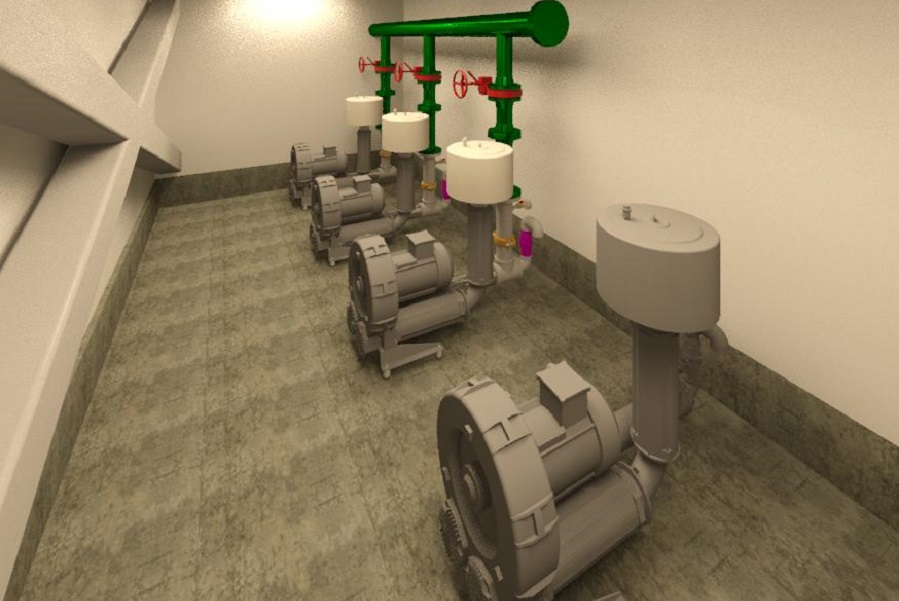

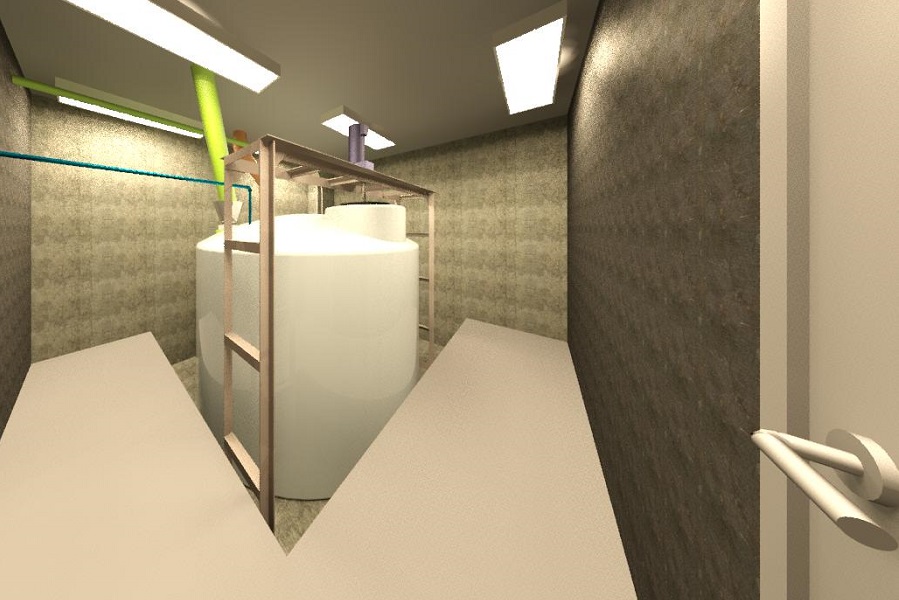

3D Renders to Identify Water Treatment Plant Design Improvements

McElhanney provided innovative 3D renderings through Revit that allowed the design team and client to virtually “walk through” the WTP building design. Equipment sourced during the progressive design project delivery process was slotted into the 3D model with “relied upon” dimensions. This created smooth coordination between interest holders and allowed the team to observe available space for day-to-day operations and maintenance, overhead risks, and tripping hazards.

Future Greenfield Water Treatment Plant Plans

McElhanney led the detailed design of a greenfield water treatment plant, in collaboration with the awarded filter supply contractor AWC Water Solutions. The twin-train water treatment system included upflow clarifiers, filtration (with backwash and air scour), UV disinfection, and chlorine disinfection. The design allows for a third filtration train to be added to the WTP in the future. It also includes building electrical, power distribution, standby generator, lighting and control, and an automation system with SCADA integration.

McElhanney provided:

- Preliminary design for process engineering (including the pilot plant design) and operational support to aid development of detailed design

- Detailed design for all engineering disciplines including process, civil, structural, geotechnical, electrical, mechanical, hydraulic modelling, and reporting

- Full project management services managing scope, budget, schedule, procurement strategy, risk management, and engineering estimates

- Project support and presentations with District engineering staff at Council meetings. Provided contract support and evaluation for the filter supply contract RFP

- Environmental permitting and liaison with the Ministry of Environment and Climate Change Strategy and full collaboration and permitting approvals including presentations to Northern Health during preliminary and detailed design